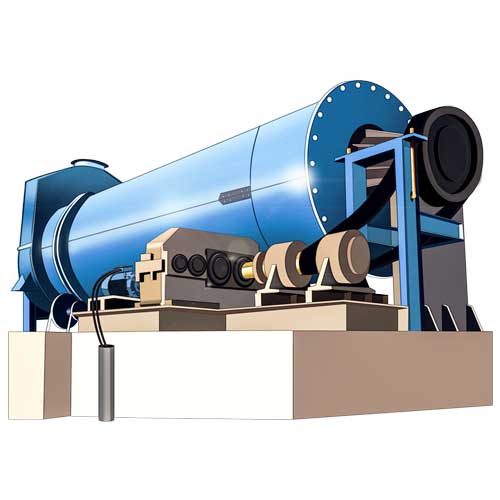

Double Shell Rotary Dryer

Application

The equipment is used to reduce moisture content in ores and minerals. The equipment is of co-current design with an inner shell fitted inside the outer shell by suitable mechanical suspensions. The wet materials containing moisture is fed from burner end in the inner shell which is heated by firing medium like FO, LDO, Coal or gas with suitable Burner system or Hot Air Generator and are progressed by Spirals, Lifters and Diverters inside the shells and dry materials come out from outer shell from feeding end. The system is also equipped with suitable dry or wet type Pollution Control System.

Capacity

5TPH – 25 TPH based on Chromite Ore against reduction of 12% moisture.